Views: 0 Author: Site Editor Publish Time: 2025-12-04 Origin: Site

The environmental crisis caused by plastic waste has become a significant issue globally, especially with single-use plastic products like straws. As the world moves toward sustainability, businesses are seeking eco-friendly alternatives to traditional plastic straws. Among the most popular alternatives are PLA (Polylactic Acid) straws, which are made from renewable plant-based resources such as corn starch or sugarcane.

In this article, we explore the significant benefits of switching to PLA straws, particularly in comparison with traditional plastic straws. Moreover, we delve into why PLA Straw Making Machines are essential for businesses looking to reduce their environmental footprint while maintaining high production efficiency.

PLA (Polylactic Acid) is a biodegradable plastic made from renewable resources such as corn starch or sugarcane. Unlike traditional petroleum-based plastics, PLA is produced from natural resources that are sustainable and renewable, making it an environmentally friendly option for businesses.

Biodegradable: PLA straws are designed to break down over time, offering a sustainable alternative to traditional plastic straws.

Compostable: In industrial composting facilities, PLA straws can be fully composted within a few months, reducing long-term waste.

Non-toxic: PLA is safe for both humans and animals, with no harmful chemicals such as BPA that are often found in plastic products.

Renewable: PLA is made from renewable plant-based resources, helping to reduce reliance on fossil fuels.

PLA straws are quickly becoming the go-to choice for businesses committed to sustainability.

Traditional plastic straws are a significant source of environmental pollution. Every year, billions of plastic straws are used worldwide, with most ending up in landfills or oceans. According to environmental reports, plastic straws are among the top 10 most common items found during beach cleanups.

Plastic straws are non-biodegradable and can take up to 200 years to decompose. This contributes to the growing problem of plastic pollution, which affects marine life, ecosystems, and the environment as a whole. Animals can ingest these straws, leading to injury or death, and plastic waste can accumulate in the oceans, harming wildlife and creating "plastic islands."

With increasing environmental awareness, many countries have implemented or are planning to implement bans on single-use plastic products, including plastic straws. As a result, there is an urgent need for businesses to transition to more sustainable alternatives, such as PLA straws, which are environmentally friendly and compostable.

The production of PLA straws involves several key steps that can be efficiently handled by a PLA Straw Making Machine. Here's an overview of the process:

The process begins with the preparation of PLA pellets, which are the raw material for the production of straws. These pellets are made from PLA resin derived from plant-based materials like corn starch. The pellets are carefully measured and loaded into the machine's hopper.

Once the PLA pellets are ready, they are fed into the PLA Straw Making Machine, where they undergo a melting process. The melted PLA is then extruded through a mold or die to form the desired shape of the straw. The diameter and length of the straw can be adjusted depending on the machine's settings.

Servo Motors: PLA Straw Making Machines use servo motors to precisely control the extrusion speed and ensure uniformity in the thickness of the straws.

PLC Control Systems: The PLC (Programmable Logic Controller) system ensures that the entire process, from temperature control to speed regulation, operates seamlessly.

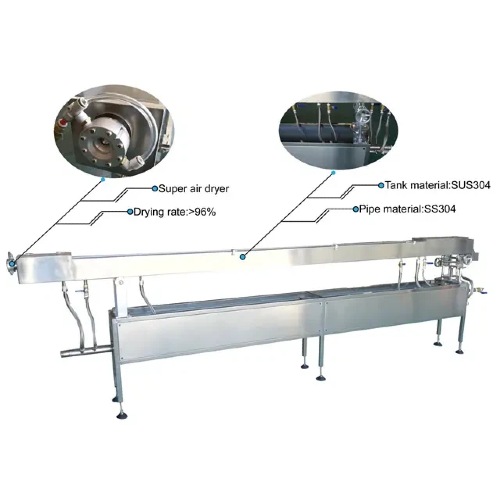

After extrusion, the straws pass through a cooling system where cold water is used to solidify the PLA material. Once cooled, the straws are cut into the desired lengths using an automated cutting system.

After cutting, the PLA straws are packaged according to the customer's needs. Common packaging methods include:

Individual Packing: Straws are packed one by one in plastic or paper wraps.

Bulk Packing: Straws are bundled together in larger bags for wholesale distribution.

Paper-Box Packing: Straws are neatly placed in eco-friendly paper boxes for retail sales.

The PLA Straw Making Machine automates this entire process, reducing manual labor and ensuring consistent packaging quality.

Step | Process | Description |

1. Raw Material Prep | PLA pellets are loaded into the hopper. | PLA resin is derived from plant-based sources like corn starch, which are prepared for extrusion. |

2. Extrusion | PLA material is melted and extruded into straws. | The melted PLA is forced through a mold to form the desired diameter and length of the straws. Servo motors and PLC control systems ensure precision. |

3. Cooling & Cutting | Cooling and cutting of straws. | Cold water solidifies the extruded PLA, followed by automated cutting into desired lengths. |

4. Packaging | Packaging options for the finished straws. | Automated packaging methods such as individual, bulk, or paper-box packing are used to ensure consistency and speed. |

Aspect | PLA Straws | Traditional Plastic Straws |

Biodegradability | Biodegradable and compostable | Non-biodegradable, can take hundreds of years to decompose |

Impact on Wildlife | Safe for wildlife; breaks down naturally | Harmful to wildlife, can be ingested and cause injury or death |

Production Material | Made from renewable plant-based resources | Made from fossil fuels (petroleum) |

Decomposition Time | Breaks down in months under composting conditions | Takes up to 200 years to degrade in the environment |

PLA Straws: PLA straws are durable for short-term use but designed to degrade after disposal. They are perfect for quick consumption, such as in restaurants or fast food outlets.

Plastic Straws: Plastic straws are built to last for a long time but persist in the environment for hundreds of years. They do not decompose easily, making them harmful to the planet.

While PLA straws may be more expensive than traditional plastic, the cost of production can be significantly reduced by using PLA Straw Making Machines. These machines offer high efficiency, automation, and flexibility, making it possible for businesses to scale production while maintaining lower labor costs.

Switching to PLA Straw Making Machines helps businesses reduce their environmental footprint. By producing PLA straws in-house, businesses can control production efficiency while ensuring that they are contributing to a cleaner planet. PLA straws are biodegradable, compostable, and derived from renewable resources, helping to combat plastic pollution.

Governments around the world are implementing plastic bans and regulations to curb environmental damage caused by single-use plastics. PLA Straw Making Machines enable businesses to comply with these regulations and produce eco-friendly products that align with new legal requirements.

Consumers are becoming more environmentally conscious, and many prefer businesses that adopt sustainable practices. By using PLA straws, companies can attract eco-conscious customers, enhance their brand image, and build long-term loyalty.

Investing in PLA Straw Making Machines is not just a step toward sustainability but also a smart business decision. These machines are designed to increase production efficiency, reduce waste, and lower overall production costs. As the demand for PLA straws grows, businesses that adopt this technology will be better positioned to stay ahead of competitors.

PLA Straw Making Machines are designed to handle high production volumes while ensuring product consistency. The automation features, including servo motors and PLC control systems, allow businesses to produce large quantities of PLA straws quickly and efficiently. Additionally, the machines can easily adjust to different straw sizes and materials, providing businesses with greater flexibility.

As businesses grow and the demand for PLA straws increases, PLA Straw Making Machines offer scalability to meet these growing needs. These machines are capable of handling both small-scale and large-scale production, ensuring that businesses can continue to produce sustainable products without sacrificing quality.

By producing PLA straws in-house with PLA Straw Making Machines, businesses can eliminate the need for purchasing pre-made straws. This not only reduces costs but also allows companies to control the production process, ensuring that the final product meets their quality standards.

Switching to PLA straws is a crucial step for businesses seeking to minimize their environmental impact while maintaining high production standards. By adopting PLA Straw Making Machines, companies can produce biodegradable PLA straws that align with the global sustainability movement. These machines not only help businesses meet environmental regulations but also cater to the growing consumer demand for eco-friendly alternatives.

Investing in PLA Straw Making Machines brings numerous long-term benefits, including reduced production costs, increased efficiency, and enhanced brand reputation. At Hangzhou Fuyang Sunrise Machinery, we offer state-of-the-art PLA straw making solutions that ensure high-quality, cost-effective, and sustainable production. Our machines are designed to help your business transition smoothly to eco-friendly practices, providing the precision and scalability needed to meet increasing demand.

Contact us today to learn how our PLA Straw Making Machines can help your business produce high-quality PLA straws and contribute to a greener future. Our team is ready to assist with all your production needs and provide tailored solutions for your business.

PLA straws are made from Polylactic Acid (PLA), a biodegradable plastic derived from renewable plant-based sources like corn starch or sugarcane.

Switching to PLA straws helps reduce plastic waste, supports sustainability, and complies with regulations against single-use plastics. PLA straws are biodegradable and compostable, offering a more eco-friendly option.

PLA straws are durable for short-term use, but they are designed to break down over time after disposal, unlike plastic straws, which persist in the environment.

A PLA Straw Making Machine extrudes PLA pellets into straws, using precision control systems to regulate temperature, speed, and dimensions. It then cools, cuts, and packages the straws.

Yes, PLA Straw Making Machines can be easily customized to produce straws of various sizes and lengths, allowing businesses to meet different customer requirements.

Switching to PLA straws allows your business to align with sustainability trends, attract eco-conscious consumers, comply with regulations, and reduce production costs over time.

PLA Vs. Traditional Plastic Straws: Why Switching To PLA Straw Making Machines Is Essential

The Technology Behind PLA Straw Making Machines And How They Operate

The Environmental Benefits of PLA Straw Making Machines And Their Role in Reducing Plastic Waste

Step-by-Step Guide To Setting Up A PLA Straw Production Line

Complete Guide To Straw Packaging Solutions: From Single Wrap To Box Packing

From Plastic To PLA: The Eco-Friendly Transformation of The Straw Industry